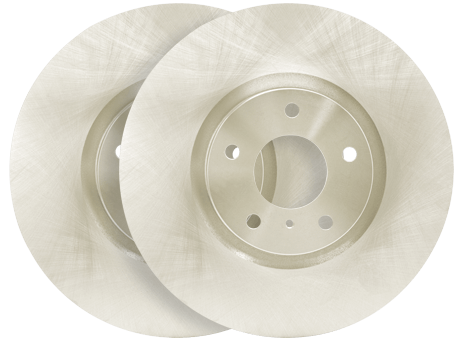

With today’s open wheels, a car’s brake components are clearly visible. DFC’s GEOSPEC Coated Brake Rotors will keep it free from rust, looking great, and keeping your customers’ happy, long after you’ve installed them.

3 Reasons Why:

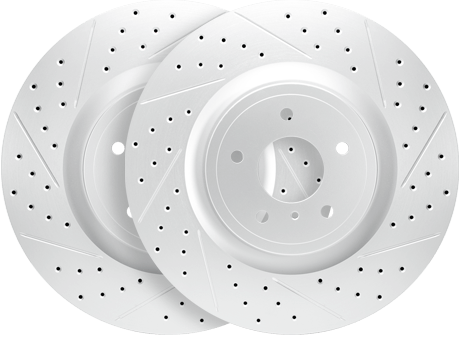

DFC GEOSPEC Coated Brake Rotors are specially coated with a special paint to form a durable and attractive silver-gray finish that fights rust far better than other conventional paint or zinc plating.

Each DFC GeoSpec Coated Brake Rotors is processed dry, shipped dry, and ready to install without any additional preparation.

An average brake job takes 1.25-2.5 hours per axle. Without the need to clean an oil covered rotor, this saves a tremendous amount of time and money during the installation process. The coating is simply and safely swept away by the friction material with no harmful effects.

• Engineered with premium G3000/G11H18 iron castings for strength, stability, and durability

• Original Equipment (OE) vane

• Provides superior corrosion protection over zinc / conventional painting

• CNC-machined to the tightest tolerances

• 100% precision cut and mill-balanced

• Non-directional finish

• Quality tested to ensure long-lasting performance

• Set at a great price

To learn more about DFC GeoSpec Coated Brake Rotors,

please visit: www.dynamicfriction.com/products/geospec

About Dynamic Friction Company

DFC is an award winning brake components manufacturer and supplier headquartered in Southern California. DFC offers a complete brake systems program for all passenger cars, pickup, & medium duty trucks. DFC is recognized for its devotion to bringing its customers the latest and greatest in brake products available without the exorbitant costs. DFC boasts a full complement of dedicated in-house engineers and R&D staff who work vigorously to give our customers first-to-market advantage and assurances that modern technological complexities are fully addressed.

UNITED STATES

UNITED STATES