Brake Shoes - From The Best Brake Parts Company

From premium friction material compounds to a 100% new carbon steel dipped with high temperature anti-rust corrosion black paint, all DFC True-Arc Brake Shoes are engineered to meet the same form, fit, and function as OEM brake shoes.

Treatment Process

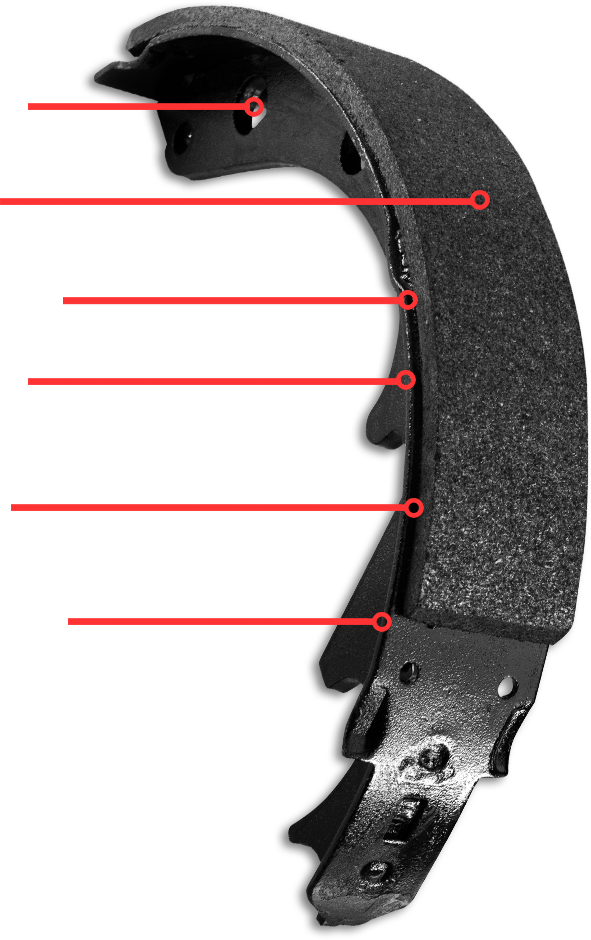

Each brake shoe, even where riveted, undergoes a unique glue lining and heat treatment process to bond the friction material to steel for superior friction retention in the most demanding applications. This reduces the chance of friction lifting and delamination that can lead to noise, vibration, rust-jacking and friction material break down.

Once the friction is bonded with the carbon steel, every DFC True-Arc Brake shoe undergoes a precision arc grinding process to ensure a true shoe-to-drum fitment. Lastly and where applicable, DFC provides attachment hardware including levers and pins.

DFC True-Arc Brake Shoes are extensively field and lab tested to ensure optimal stopping performance.

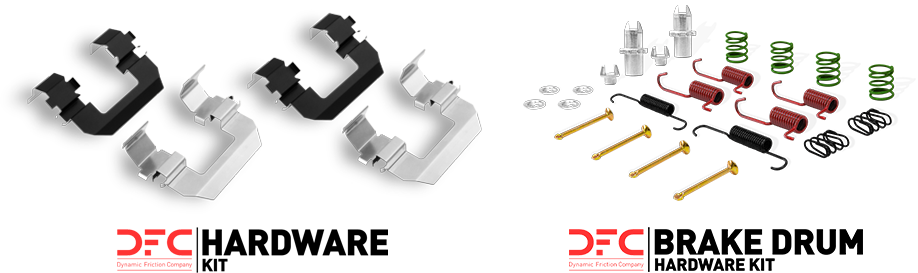

- Attachment hardware (levers & pins) included where applicable

- Precision arc grinded for perfect shoe-to-drum fitment

- Bonded or riveted per OE specifications

- 100% new carbon steel dipped with high temp anti-rust corrosion black paint

- Glue lining & treatment to ensure friction material to steel bonding

- Field and lab tested to ensure reliability and long-lasting performance

UNITED STATES

UNITED STATES