Off Road And Towing Brake Pads - Heavy Duty Brake Pads

Designed for heavier vehicles with larger brake systems, DFC Heavy‐Duty Brake Pads deliver exceptional braking performance in harsh conditions. DFC Heavy‐Duty brake pads are exclusively engineered and formulated to withstand extreme heat, heavy duty operation, frequent stopping, or towing.

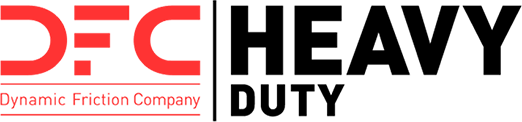

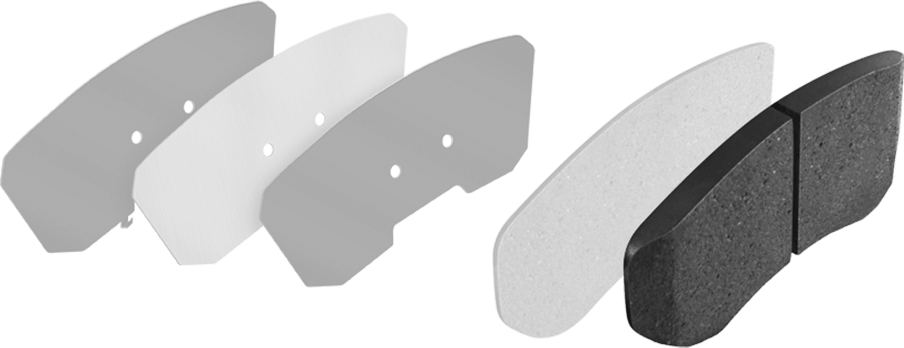

After the compound is pressed onto the backing plate, each DFC Brake Pad is 100% post cured to ensure stable friction performance. Each pad is then scorched to remove uncured bonding agents to minimize the need for initial break-in period and increase stopping power from the initial stop

Post CuredScorched

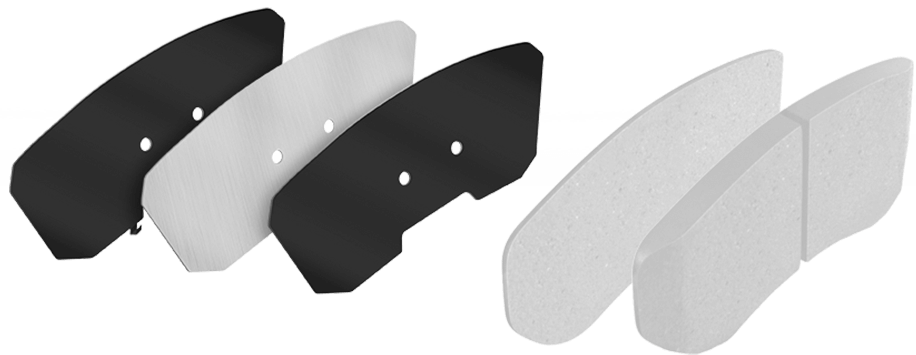

Lastly, the pads assembled with DFC Premium Rubber-Steel-Rubber shims for improved NVH (noise, vibration, and harshness) characteristics.

DFC Premium

Rubber-Steel-Rubber Shims

- Promotes better friction to plate adhesion, minimizing noise.

- Acts as a thermal barrier by minimizing the heat transfer from the pad into the caliper, reducing the possibility of fluid boil.

Underlayer

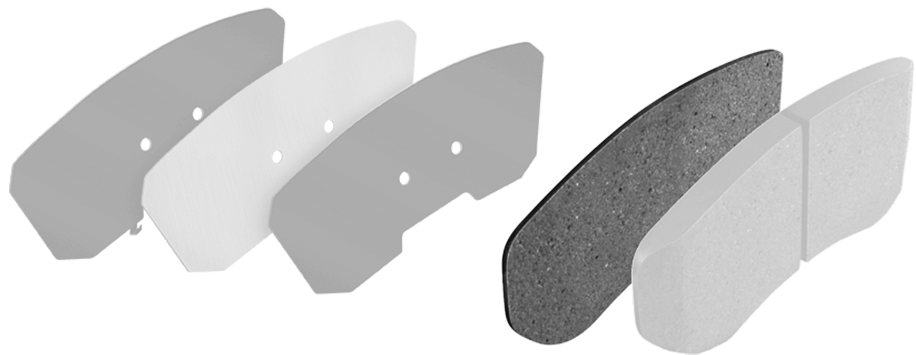

- Frequent braking environments, high speed, heavy traffic, steep gradients, towing, or off-roading

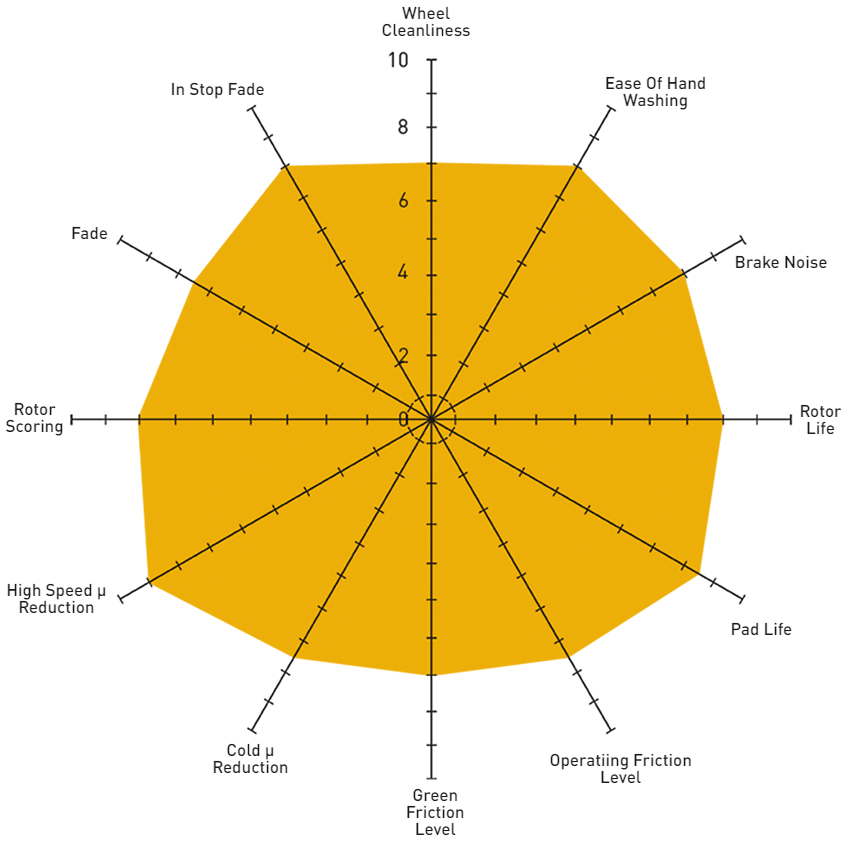

- Delivers strong, predictable friction level regardless of temperature, speed, or axle load

- Engineered to withstand extremely high operating temperature range

- Long pad wear, low noise, and low dust

- 100% Copper Free Eco Friendly Formulation [California/Washington 2025 Compliant-Leaf Mark N]

& PERFORMANCE FEATURES

- Chamfered and Slotted (where applicable) to reduce noise when braking

- Scorched to remove uncured bonding agents, minimizing the need for initial break-in period and increasing stopping power from the initial stop.

- Positive mold to promote consistent friction material density

DFC Heavy Duty Brake Pads are environmentally friendly and

adhere to the low copper requirements under California and

Washington restrictions for 2021 / 2025.

UNITED STATES

UNITED STATES