Choose the best rotors for trucks with confidence. This comprehensive guide tackles the hard decisions by comparing durability, design, and performance for safe, responsive braking. Whether you’re everyday hauling or taking on tough terrain, let us steer you through the brands that stand up to your truck’s challenges.

Key Takeaways

- Choosing the right rotors for a truck is essential for compatibility and performance, and this choice should take into account the vehicle’s make, model, and the driver’s typical usage, such as daily commuting, heavy hauling, or off-roading.

- Rotor materials vary, with cast iron offering durability and consistency, while composites provide higher performance but at a higher cost; coated rotors may be more expensive initially but can offer longer life and less maintenance over time.

- Full brake kits provide a comprehensive solution for braking system upgrades, ensuring all parts work together effectively, while individual rotors can be a budget-friendly option or suitable for custom brake system setups.

Selecting the Right Rotors for Your Truck’s Needs

Choosing the appropriate rotor for your truck is as crucial as picking out the right set of shoes. They need to match and be designed for the task ahead.

Moving forward, we will dive into aligning your choice of rotors with both the specific characteristics of your vehicle and how you drive it. This alignment is vital in achieving enhanced braking performance that delivers when you need it most.

Year, Make, Model Considerations

To fully tap into your vehicle’s capabilities on the open road, it’s crucial for the rotors to be as distinctive as the truck itself. Custom-designed options like DFC Carbon Alloy Performance Brake Rotors are engineered for exact fitment to specific vehicles, which streamlines installation, eliminates potential issues and ensures a perfect match—reinforced by quality guarantees and warranties.

Hence, prior to embarking upon your forthcoming journey, ensure that your set of brake rotors is crafted with endurance in mind specifically for your unique make and model.

Driving Style and Rotor Types

Consider your driving style: are you the daily driver, drives on uneven terrain, or the drives often with heavy loads? Your choice of rotor should reflect this. Blank or smooth rotors cater to the everyday driver, offering quiet and efficient braking power without fanfare.

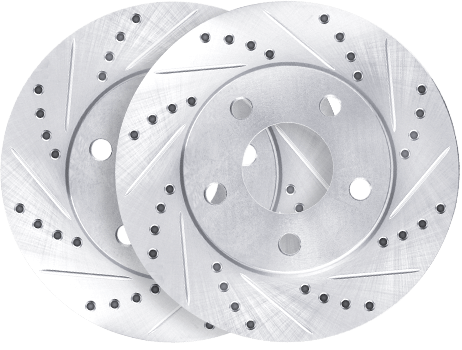

However, if your truck doubles as a workhorse, hauling heavy loads or navigating steep terrains, drilled and slotted rotors with drilled holes, like those from DFC Premium Performance, are the go-to.

These rotors are engineered to dissipate heat and maintain braking performance under pressure, a critical factor for those who demand more from their vehicles.

Remember, the right rotor can mean the difference between a wheel that stops and a wheel that excels.

Special Requirements for Towing and Off-Roading

For trucks that engage in intensive activities such as towing and off-road adventures, a stock brake system may not suffice. Such tasks demand rotors with enhanced stopping power to cope with the additional heat generated by these strenuous conditions.

Specifically designed for this purpose are drilled and slotted rotors made of carbon alloy, which excel at absorbing heat—crucial when dealing with the added weight and pressure from towing.

Having the right materials isn’t enough. Upgrading to a full brake kit specifically engineered for heavy-duty use can significantly improve your truck’s ability to stop effectively on challenging terrains or while hauling heavy loads. This upgraded setup offers dependable performance beyond what standard brakes provide, ensuring consistent stopping force under hard road conditions or when managing significant towed weights.

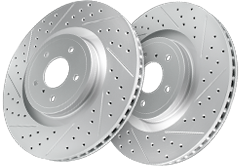

The Pros and Cons of Different Rotor Materials

The choice of rotor material is as significant as the rotor’s size, with each offering distinct advantages and drawbacks. Cast iron rotors provide traditional dependability, whereas composites offer better performance at a higher cost. This section will help you discern the best material for enhancing your truck’s braking power.

Cast Iron Versus Composite Rotors

When discussing brake rotors, two common types are cast iron and composite. Cast iron is known for its long-lasting nature and consistent performance. However, it’s heavier, which might not be ideal for those looking to lighten their vehicle. Composites, on the other hand, are lighter and can offer better heat resistance, but they come at a higher price.

Conversely, composite rotors are recognized for their superior operational capabilities and admirable resistance to heat-induced deformation during intense use. These high-carbon-content rotors cater to individuals desiring the latest advancements in fade-resistant rotor technology—provided they can accommodate the cost associated with these materials.

Coated Rotors: Are They Worth It?

Yes, coated rotors are worth it to have despite it being more expensive than the traditional cast iron rotors.

Zinc-coated rotors offer enhanced protection against rust and corrosion, potentially extending the life of the rotors and maintaining their appearance.

DFC’s coated rotors serve as defenders against these elements by preventing rust and corrosion, which prolongs your rotor’s lifespan. Although they might cost more upfront, over time the enhanced durability and reduced maintenance can render coated rotors a worthwhile investment for your vehicle.

This choice involves balancing current expenses with prospective advantages to guarantee that the brakes on your truck stay operational and aesthetically pleasing over extended periods.

Full Brake Kits vs. Standalone Rotors

Opting for a full brake kit versus selecting just standalone rotors is akin to the choice between ordering an entire gourmet feast or picking individual dishes. When you invest in a full brake kit, it’s like receiving an all-inclusive set tailored for complete revitalization of your braking system. The perks include:

- Improved resistance to heat

- Steady and reliable performance

- Minimized occurrence of brake fade

- Reduced accumulation of dust on wheels due to decreased brake dust emission

On the other hand, purchasing stand-alone rotors can be particularly attractive if one’s intention is to rectify a specific problem or when financial constraints are at play. In forthcoming sections, we will explore in greater detail the advantages and relevant situations where each option may prove beneficial.

Benefits of Complete Brake Kits

Selecting a comprehensive brake kit is a significant enhancement for your truck, providing an integrated solution that encompasses pads, rotors, and essential hardware designed to synergize for peak performance and safety. The advantage of purchasing these kits often lies in their combined pricing structure, which offers economic benefits over buying each component individually. The convenience offered by acquiring everything needed in one complete set streamlines the upgrade experience—guaranteeing you have all critical parts on hand promptly—and prepares you effectively for any intense towing or hauling jobs.

By installing complete brake kits onto your vehicle, it’s not just an improvement of the brakes themselves. It’s an investment into bolstering your truck’s braking effectiveness substantially when faced with demanding conditions.

When to Choose Individual Rotors

Sometimes, the meticulous process of choosing specific rotors is crucial. When operating on a limited budget or dealing with only one damaged rotor, it makes sense to purchase individual rotors. This allows for focused repairs without unnecessary expenditure on still-functional parts.

In cases where there’s slight warping of the rotor, resurfacing could be an economical option that prolongs its service life rather than outright replacement.

For enthusiasts who take pride in customizing their braking systems, selecting separate rotors provides flexibility. It enables them to pair particular types of pads and caliper configurations with their unique driving preferences.

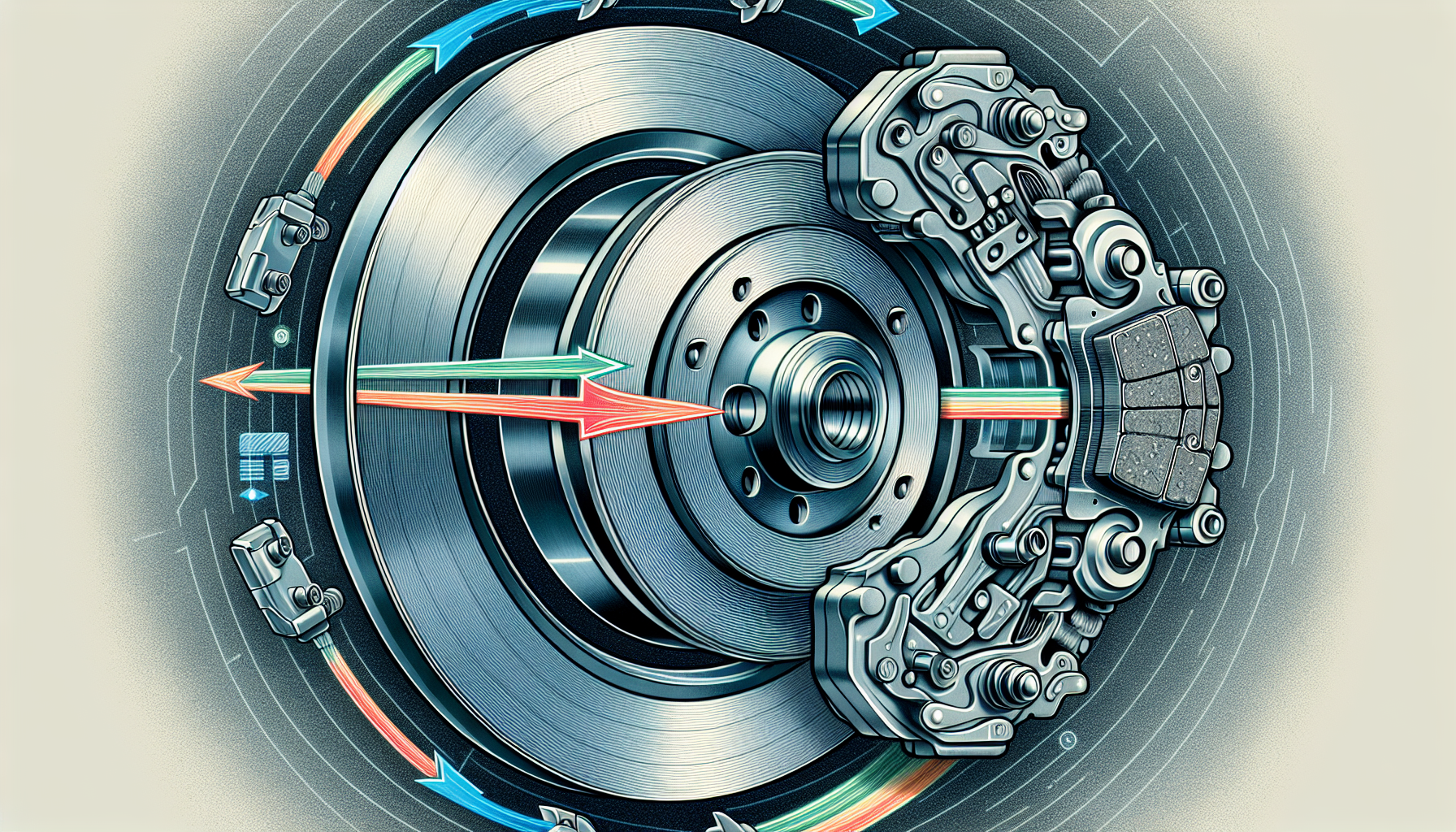

Essential Companion Parts: Pads and Hardware

A perfectly functioning braking system requires the synchronized operation of rotors, pads, and hardware. It is imperative to replace brake pads in conjunction with rotors to ensure your truck achieves the safest and most reliable stop possible. These elements work collaboratively during braking. If one part is worn out while the other remains new, it can cause diminished performance, unwanted noise, and vibration.

To maintain your truck’s optimal braking efficiency, we’ll delve into pairing brake pads with rotors correctly as well as discuss why upgrading hardware is essential for top-notch functionality.

Matching Brake Pads to Rotors

It’s crucial that your truck’s brake pads work well with the rotors. Choosing high-quality pads designed for your specific truck can greatly improve stopping power and extend the life of your rotors. Well-known brands like Dynamic Friction and R1 Concepts are often recommended for their reliable and long-lasting brake pads.

Hardware Upgrades for Peak Performance

Make sure not to disregard the minor elements of your brake system. Worn-out brake hardware can cause a range of complications, including warping and noise issues. By incorporating new hardware with each replacement of a brake kit, as offered by companies such as Dynamic Friction, you maintain optimal braking efficiency and address possible concerns early on.

Even when existing clips and shims appear to be in good condition, it’s beneficial to replace them to promote uniform contact across the braking surfaces and hinder early deterioration. Components like stainless steel shims are effective at significantly minimizing noise levels during braking for an improved driving experience.

Summary

When looking for the ideal brake rotors for your truck, you’ve explored a variety of choices. From understanding what your truck needs to picking the best rotor type and brand, it’s clear that the right combination of rotors, pads, and hardware is key to a well-functioning brake system. No matter your driving needs—daily commuting, heavy-duty hauling, or off-roading—the correct brake components will help your truck stop effectively and safely. Use this guide as your roadmap to a superior braking system that not only fulfills but surpasses your performance expectations.

Frequently Asked Questions

How much are rotors for a suv?

The cost of brake rotors for an SUV falls between $150 and $300 per axle just for the components. If you opt to have a professional mechanic perform the rotor replacement, expect to pay an extra fee ranging from $150 to $250.

Which rotors last the longest?

Typically, vented rotors outlive solid ones due to their enhanced resistance to heat-induced cracking and also help in reducing wear on the brake pad. Consequently, they are a favorable option for those seeking durable rotors.

Are slotted rotors better for a truck?

Indeed, trucks equipped with slotted rotors experience enhanced braking capabilities due to better heat dissipation, reduced wear and tear, and diminished noise levels. It’s crucial to opt for premium quality slotted rotors as there is a heightened danger of them cracking if they are not.

Carrying out routine cleaning and thorough inspections forms an essential part of their upkeep.

What considerations should I take into account when choosing brake rotors for my truck?

When selecting brake rotors for your truck, take into account the specific year, make, and model of your vehicle. Factor in your driving habits and any unique needs such as towing or engaging in off-road activities.

It’s critical to confirm that the rotors you choose are not only compatible with your truck but also offer performance that meets the demands of your particular driving conditions.

UNITED STATES

UNITED STATES

![What Are The Types Of Rotors That Are Great for Trucks [Guide And Info]](https://www.dynamicfriction.com/blog/wp-content/uploads/2021/10/geospec-rotors-825x510.jpg)