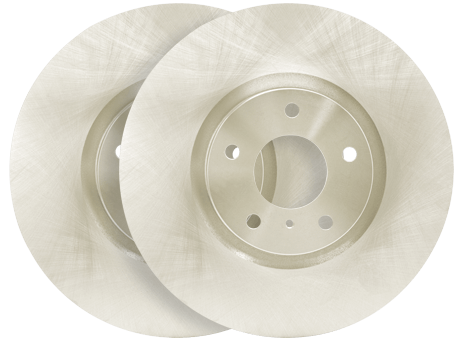

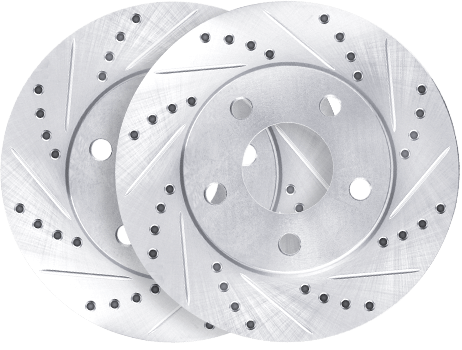

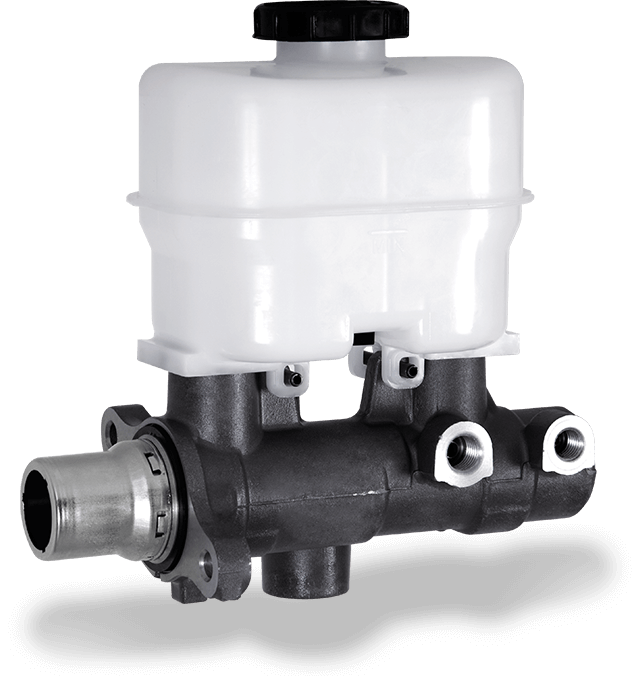

We’ve heard you loud and clear! Many of you had voiced your requests for a comprehensive brake kit package in order to meet your customer demands. And in the spirit of market demand we did it. We listened and immediately went to work in creating a custom brake kit program ready to order. You may now offer your customers a complete DFC premium brake kit with a choice of DFC Friction, Rotor and/or hardware combination.

The DFC Brake Kit program will make available several variations depending upon need and desire:

Watch the New DFC Brake Kits Video

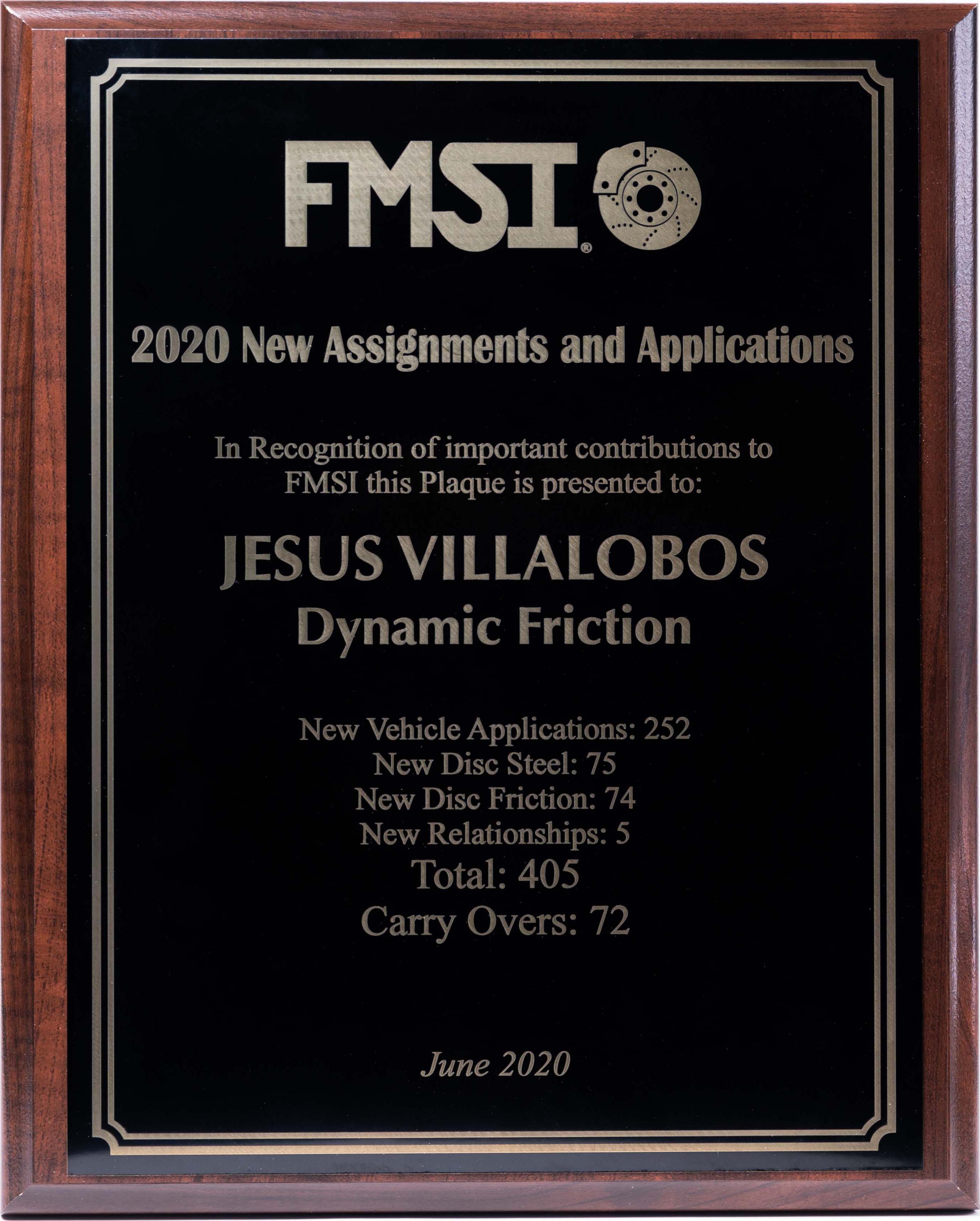

About Dynamic Friction Company

DFC is an award winning brake components manufacturer and supplier headquartered in Southern California. DFC offers a complete brake systems program for all passenger car, pickup, & medium duty trucks. DFC is recognized for its devotion to bringing its customers the latest and greatest in brake product available without the exorbitant costs. DFC boasts a full complement of dedicated in-house engineers and R&D staff who work vigorously to give our customers first-to-market advantage and assurances that modern technological complexities are fully addressed.

UNITED STATES

UNITED STATES