Looking to choose the right rotor types for Honda Civic? This guide breaks down stock, slotted, drilled, and performance rotors, helping you find the best fit for your driving style and performance needs.

Key Takeaways

- Stock rotors offer cost-effective reliability for everyday driving but may lack performance under high-stress conditions.

- Performance slotted rotors and drilled rotors enhance braking performance for high-stress scenarios but can increase noise and wear.

- Choosing the right rotors and brake pads, considering driving style, performance needs, and budget, is crucial for optimal braking performance.

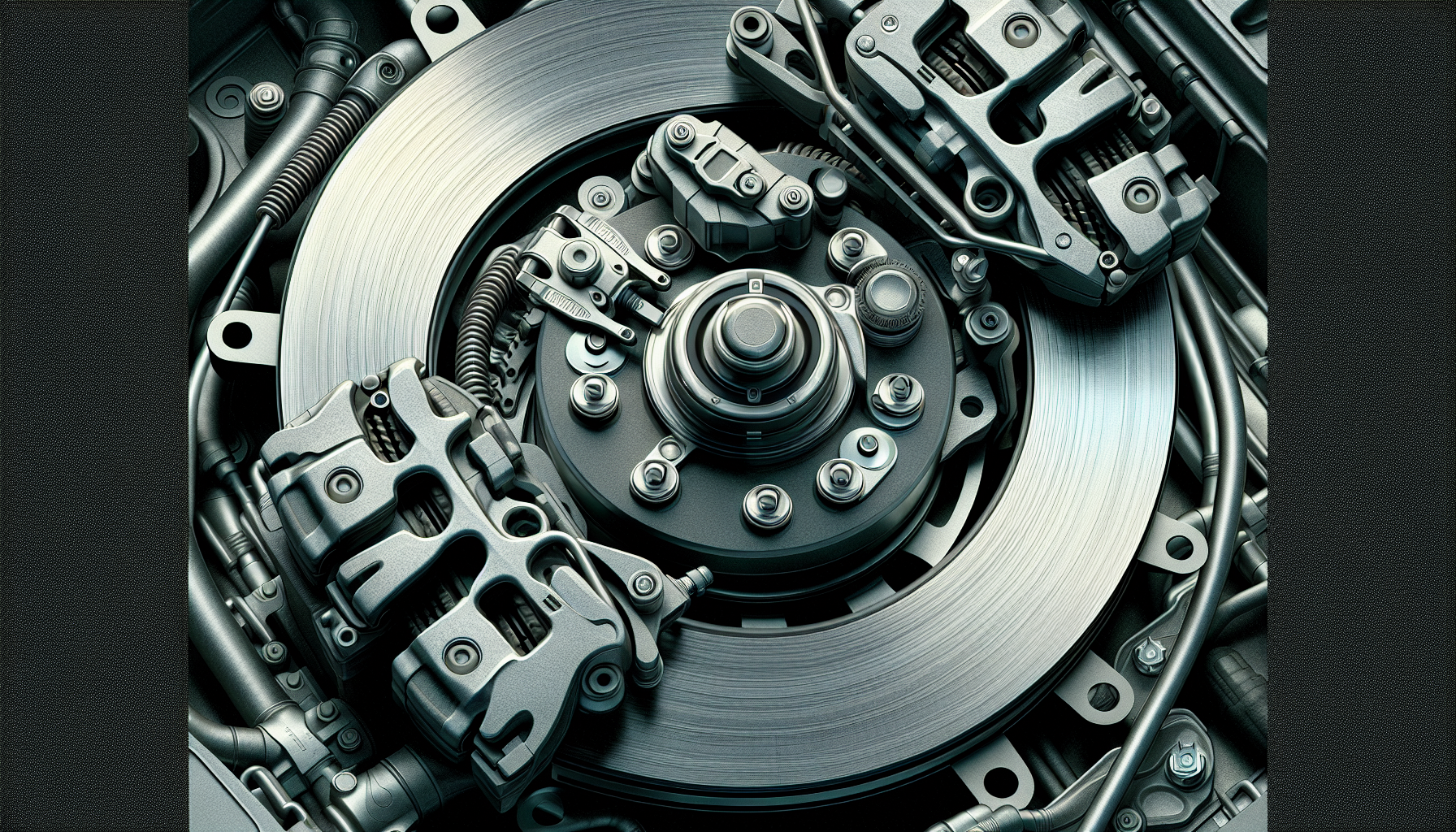

Stock Rotors

The stock rotors on a Honda Civic are designed to provide reliable braking performance for everyday driving. These rotors are known for their longevity, often lasting up to 50,000 miles under normal driving conditions. They are typically made from durable materials that don’t require replacement unless there is significant wear, cracking, or they fall below the minimum thickness specifications.

For most Honda Civic owners, the standard rotors offer a cost-effective solution that doesn’t compromise on reliability. These blank rotors, which come factory-installed, provide a balance of performance, durability, and low noise, making them ideal for everyday use. They are designed to perform adequately without producing excessive noise or dust, ensuring a smooth and quiet driving experience.

However, stock rotors do have their limitations. They don’t feature advanced coatings or slotting, which means they may not perform as well under high-stress conditions or during intense driving scenarios. If you’re looking to enhance your Honda Civic’s braking performance, you might want to consider upgrading to performance slotted or drilled rotors.

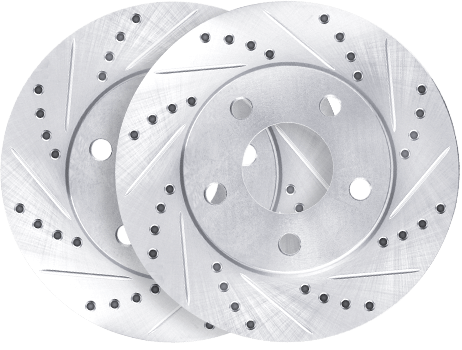

Performance Slotted Rotors

For those who push their Honda Civic to the limits, performance slotted rotors can be a game-changer. These rotors are designed with grooves that help dissipate heat and gases, preventing brake fade during intense driving conditions. This makes them particularly beneficial for high-performance and racing scenarios where responsive and powerful braking is crucial.

One of the significant advantages of slotted rotors is their ability to reduce friction in the brake pads, leading to consistent stops and less noise. They also perform exceptionally well in wet conditions by removing water and debris from the brake pads, ensuring reliable braking even in adverse weather. Despite the potential for increased noise and wear, the enhanced braking performance makes them a popular choice among enthusiasts.

Consider the Honda Civic Type R, renowned for its high-performance capabilities. Slotted rotors significantly enhance its responsiveness and stopping power. If a performance upgrade is what you’re after for your Civic, slotted rotors could be an excellent choice.

Drilled Rotors: Pros and Cons

Drilled rotors are another popular option for enhancing brakes performance, but they come with their own set of advantages and disadvantages. These rotors feature holes drilled through them, which enable better cooling and water dissipation. This can be particularly beneficial in preventing brake fade and ensuring consistent performance during high-stress driving conditions.

However, the drilling process can weaken the rotor structure, making them susceptible to cracking under severe stress. This is especially true in racing or other high-performance scenarios where the rotors are exposed to extreme temperature changes. Over time, these cracks can develop, potentially compromising the rotor’s integrity and performance.

Drilled rotors, despite their superior cooling and water dissipation, might be overkill for everyday city driving. The potential for cracking and their relative costliness could outweigh their benefits for regular use. Before opting for drilled rotors, a careful consideration of their advantages and drawbacks is necessary.

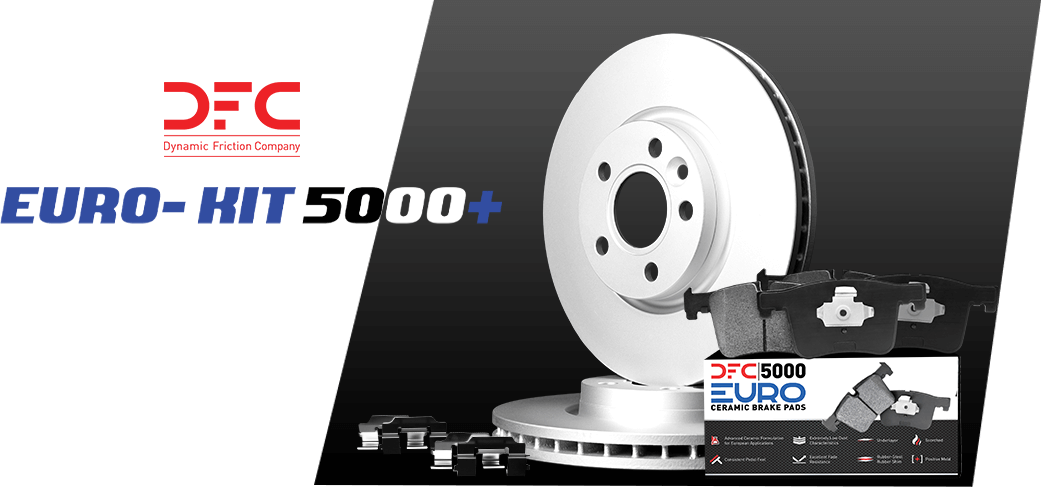

Best Rotor Kits for Track Use

If you’re taking your Honda Civic to the track, you’ll need rotors that can handle the intense conditions. High-quality brake rotors from trusted brands like Dynamic Friction offer better stopping power and heat dissipation, making them ideal for track use. These rotors are designed to maintain performance under high-speed or extreme conditions, such as racing or hauling heavy loads.

Paragon’s two-piece rotors are a popular choice for the Honda Civic Type R, known for their performance under high-stress conditions. These rotors feature composite carbon alloy metallurgy, which provides enhanced durability against deformation under extreme track conditions.

Another excellent option is DFC’s drilled and slotted rotors, a direct replacement paired with ceramic pads, which offer solid performance for aggressive driving.

For track use, slotted rotors, also known as disc rotors, are particularly advantageous due to their ability to expel dust, gases, and water, helping to maintain lower temperatures and prolong the rotor’s lifespan.

Investing in a high-quality rotor kit can make a significant difference in your track performance, ensuring you can push your Honda Civic to its limits with confidence.

Noise and Dust Considerations

Noise and dust implications are important to consider when upgrading your rotors. Slotted rotors can cause increased noise and faster brake pad wear due to the enhanced friction. This is especially noticeable when braking from high speeds, where slotted rotors can produce a rumble noise. Drilled rotors can also develop concentric grooved lines, which may produce noise as they wear.

Blank rotors:

- Produce very little dust

- Generally quiet in operation

- May not offer the same performance benefits as slotted or drilled rotors

- Tend to have a shorter lifespan

- Can reduce the life of brake pads, potentially increasing dust

The type of brake pads you use can also impact noise and dust levels. OEM pads are often metallic, leading to excessive dusting and rotor wear, whereas DFC pads are noted for being less aggressive on the rotor surface.

Choosing the right combination of rotors and brake pads can help minimize noise and dust while maximizing performance.

How to Choose the Perfect Pair of Rotors

Choosing the ideal rotors for your Honda Civic means aligning them with your specific driving style and requirements. For aggressive driving or high-performance scenarios, performance rotors, such as slotted or drilled options, are ideal. On the other hand, regular stock rotors might suffice for daily driving, providing a cost-effective solution without compromising on reliability.

Budget considerations also play a crucial role in your decision. Here are some options to consider:

- High-end options like Brembo offer exceptional performance and durability, but they come at a higher price.

- More affordable alternatives, such as Dynamic Friction, provide good performance without breaking the bank.

- Additionally, consider rotors with specific coatings, like geomet, which prevent corrosion and rust, extending the rotor’s lifespan.

Ultimately, the perfect pair of rotors for your Honda Civic will depend on your driving habits, budget, and performance needs. Taking the time to evaluate these factors will ensure you make an informed decision that enhances your car’s braking performance.

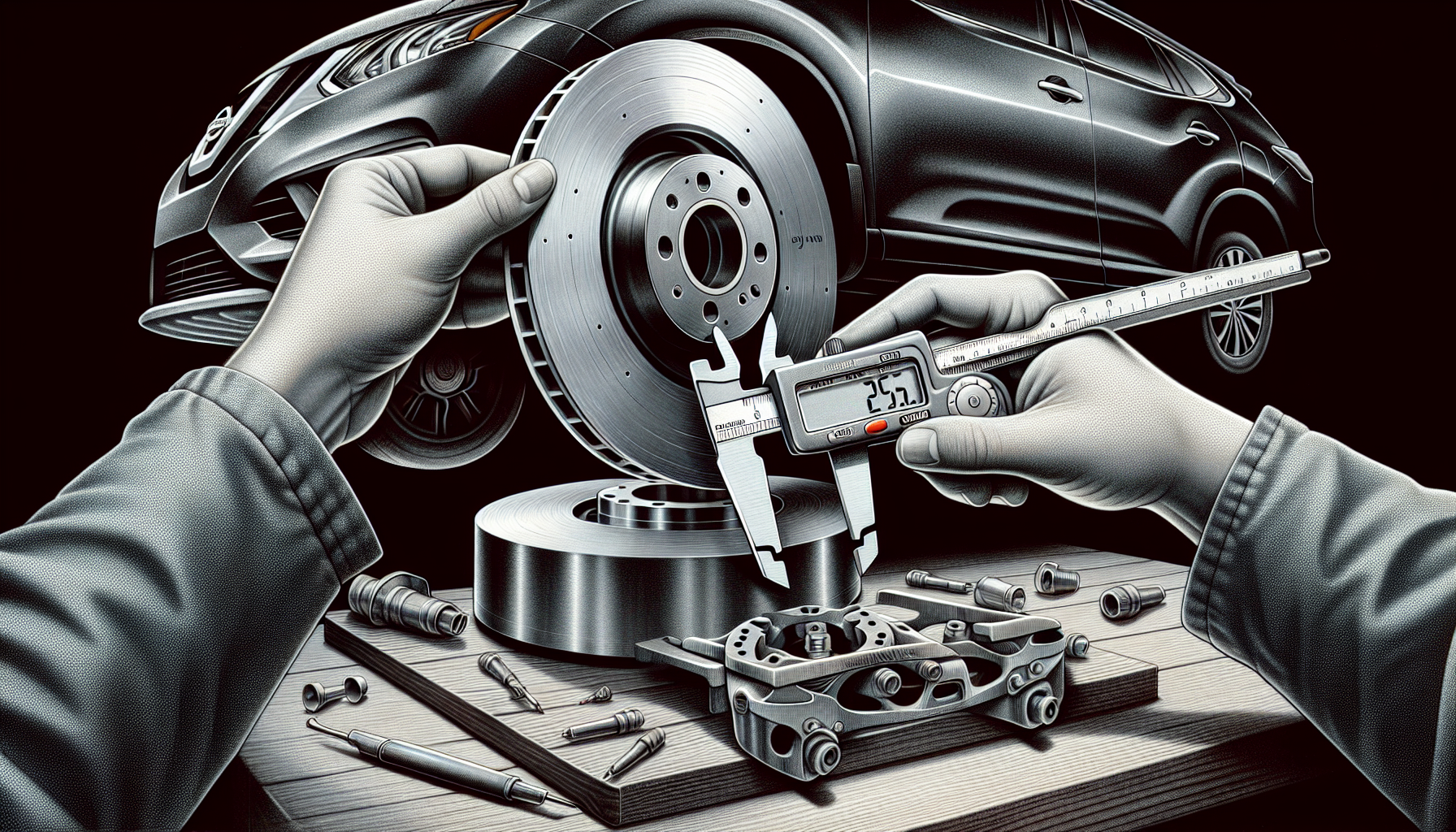

Installation Tips and Tricks

With the right tips and tricks, new rotor installation can be fairly straightforward. Here are the steps to follow:

- Use a 3/4 socket to remove the lug nuts and take off the tire.

- Spray the new rotors with brake cleaner before installing them to remove any protective coating.

- Properly install the new rotors.

- Evenly torque the lug nuts to prevent rotor warp.

Following these steps will ensure a successful rotor installation.

While the caliper brackets are off, service the slider pins and boots to prevent seizing. Clean or replace the pad sliders to avoid jamming. Use a 14mm socket to remove the bolts on the top and bottom of the caliper, and a 12mm socket to remove the two bolts securing the brake pads.

If the rotor screws are difficult to remove, hitting them with a hammer and a screwdriver can help. An impact screwdriver is highly recommended for removing stubborn rotor screws. Applying anti-seize between the hub and the new rotor can prevent rust from sticking them together. Following these tips can make the installation process quicker and more efficient.

Improving Brake Pads Compatibility

To ensure optimal braking performance, it’s crucial that you pair the right brake pads with your upgraded rotors. Ensure your rotors are compatible with your existing brake pads for the best results. Switching from organic to ceramic brake pads might necessitate resurfacing or replacing the rotors. If the rotors are in good condition and meet thickness specs, resurfacing may not be required.

Different types of brake pads offer various benefits. Here are some options to consider:

- Semi-metallic brake pads: These are durable and suitable for high-performance cars that require heavy braking.

- Ceramic pads: These are often preferred to avoid metallic dust, even if they don’t inherently improve braking capacity.

- Organic brake pads: These are recommended for lighter, compact vehicles due to their adequate stopping power and minimal noise.

Medium-sized cars benefit from low-metallic NAO brake pads, which offer enhanced stopping power despite the increased noise. Sports cars should use semi-metallic or high-performance ceramic brake pads for optimal braking performance. Choosing the right brake pads can significantly improve the compatibility and performance of your upgraded rotors.

Manufactured in the USA: Quality Assurance

Opting for rotors manufactured in the USA yields numerous advantages, including:

- Strict quality control standards for enhanced performance and safety

- Use of high-quality materials, which can enhance the durability and lifespan of the product

- Supporting local manufacturing, which helps maintain jobs and advances technological innovations within the country.

Locally manufactured rotors offer the following benefits:

- Better customer support and easier access to replacement or warranty services

- Support for local businesses and contribution to the domestic economy

- High standards of quality and reliability

When you invest in USA-made rotors, you can expect these advantages.

In conclusion, opting for rotors manufactured in the USA offers several benefits:

- You get a product that not only performs well but also supports the local economy.

- You can enjoy the benefits of quality assurance and customer support.

- It is a wise choice for any Honda Civic owner looking to upgrade their braking system.

Customer Reviews and Ratings

Turning to customer reviews and ratings can provide insightful guidance when selecting the best rotors for your Honda Civic. Many users report high satisfaction levels with the rotor types used on their vehicles. Positive feedback often highlights the enhanced braking performance noticed after installation. Performance slotted rotors, in particular, receive praise for their improved stopping power.

However, some customers have mentioned issues such as increased noise or dust with specific rotor types. It’s essential to read reviews and consider these factors when making your decision. The durability and reliability of certain rotor types are also frequently appreciated, with many users noting the long lifespan of their upgraded rotors.

Before placing your order, take the time to review customer feedback and ratings. Look for special discounts and consider the terms of any warranties or guarantees offered. This will help you make an informed decision and ensure you’re satisfied with your purchase.

Summary

In summary, upgrading your Honda Civic’s rotors can significantly enhance your braking performance. Stock rotors provide reliable and cost-effective braking for everyday driving, while performance slotted and drilled rotors offer superior stopping power for high-performance and track use. Each type of rotor comes with its own set of benefits and drawbacks, so it’s essential to choose the one that best matches your driving style and budget.

Consider the impact of noise and dust when selecting your rotors, and ensure compatibility with your brake pads for optimal performance. Installation can be straightforward with the right tips and tricks, and choosing rotors manufactured in the USA guarantees high quality and support.

By taking the time to research and select the perfect pair of rotors for your Honda Civic, you’ll enjoy improved braking performance and a safer driving experience. Don’t wait to make this essential upgrade—your car and your safety will thank you.

Frequently Asked Questions

What is the lifespan of stock rotors on a Honda Civic?

The lifespan of stock rotors on a Honda Civic is typically around 50,000 miles under normal driving conditions.

Are slotted rotors better than stock rotors?

Yes, slotted rotors offer better braking performance, especially in high-performance scenarios, by reducing friction and dissipating heat and gases.

Do drilled rotors crack easily?

Yes, drilled rotors can crack easily under severe stress, particularly in high-stress conditions such as racing. Be mindful of the stress levels to prevent cracking.

How can I reduce noise and dust from my brakes?

To reduce noise and dust from your brakes, consider using the right combination of rotors and brake pads, like DFC pads, for improved performance.

Why should I choose rotors manufactured in the USA?

You should choose rotors manufactured in the USA because they are made with stringent quality control standards, high-quality materials, and support the local economy.

UNITED STATES

UNITED STATES