Brake rotors for uneven terrain must confront intense strain and variable conditions. This article cuts through the complexity to help you identify rotors that deliver dependable performance and safety on challenging surfaces – no fluff, just the facts you need to make an informed decision.

Key Takeaways

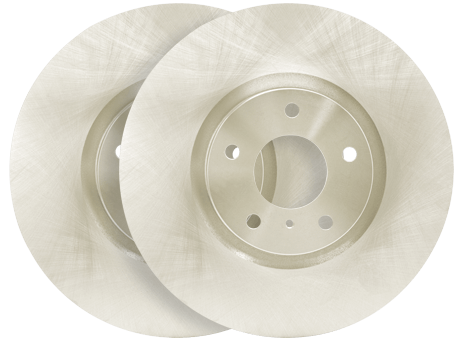

- Solid smooth rotors are generally the best choice for uneven terrain due to maximum pad contact, as opposed to drilled and slotted rotors which can reduce pad contact and are more prone to wear and cracking.

- Thicker and high-carbon cast iron rotors are ideal for uneven terrain, as they dissipate heat effectively and manage the stress of heavy braking, thus minimizing brake fade and extending the rotor’s lifespan.

- Proper rotor maintenance, such as ensuring flatness, correct hat geometry, and compatible brake pads, is crucial for maintaining braking efficiency on rough roads and avoiding issues like warping and uneven wear.

Choosing the Right Rotors for Uneven Terrain

The brake rotors are critical to the function of your vehicle’s braking system. They provide a surface on which the brake pads create friction, enabling your car to accelerate. Due to varying pressure and contact from the brake pads when driving over uneven surfaces, these rotors are subject to continuous change and must be resilient enough for consistent use. Choosing substandard rotors can significantly affect how consistently and effectively you can stop while navigating rugged terrain.

Durable rotors not only boost vehicular safety but also preserve reliable braking in diverse conditions typical of bumpy landscapes. To pick out an appropriate rotor for your automobile, it is crucial that you consider:

- The variety of rotor designs

- Their respective thickness levels

- Composition materials

- Techniques aimed at optimizing pad-to-rotor contact

Incorporating all these considerations along with utilizing proper brake fluid and ensuring the good condition of your brake pedal will enhance overall performance within your vehicle’s braking system during operation.

The Best Rotor Type For Uneven Terrains

thick plain rotors, preferably made with heat resistance materials such as carbon with vanes are the ones you need if you always drive on areas with uneven terrain. hese provide an even surface that enables optimum interaction with the brake pads—a critical factor for efficient braking on irregular terrain

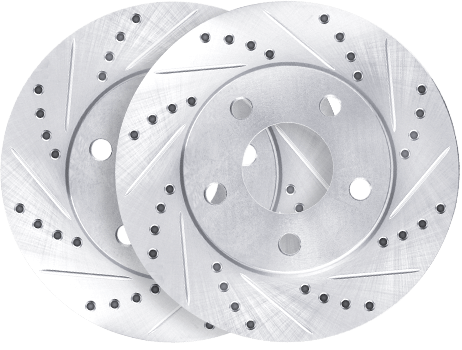

There are mainly three types of rotors: smooth, slotted, and drilled and slotted. Each of the patterns has a purpose, you can read it right here, but the ones with slotted, drilled and combination of both will not be suitable for uneven terrains.

The visual appeal of drilled and slotted rotors notwithstanding, they come with several potential downsides.

- There is a tendency towards quicker wear of brake pads

- Proneness to cracking under certain conditions increases

- Resurfacing them can be extremely difficult if not impossible

For general daily driving needs—outside of professional racing environments—and specifically when navigating bumpy roads or handling lug nuts routinely encountered in non-racing scenarios, these styles of rotors are not advisable.

Importance of Rotor Thickness and Material

Thicker, high-carbon cast iron rotors are essential for driving on uneven terrain, as they efficiently manage heat and reduce the risk of brake fade during heavy use. Their robust construction ensures long-lasting performance and durability in challenging conditions. Material quality and rotor thickness are critical factors in maintaining effective braking on rough roads.

Ensuring Maximum Pad Contact

To attain effective braking, particularly on uneven terrains, it is essential to maintain maximum pad contact. Here are a few recommendations for enhancing flatness and ensuring the brake pads fully engage.

- Employing flat rotors aids in achieving desired flatness and maximizes pad contact which is crucial when navigating roads that have varying heights.

- Proper alignment of rotor hat geometry is necessary so as not to restrict pad contact thereby preserving efficient braking capabilities.

- Prioritize precise production processes and meticulous finishing of rotors in order to guarantee their optimal level of flatness enabling extensive brake pad engagement.

Adhering to these suggestions will lead to betterment in your vehicle’s ability to slow down or stop on bumpy road surfaces.

Consistency in the interaction between brake pads and rotors plays an integral role. Thus, both components – the rotor as well as the brake pad – significantly contribute towards enhancing overall braking performance.

Addressing Heavy Braking and Heat Dissipation

Navigating through rough terrains often demands continuous heavy braking, which in turn produces a significant amount of heat. This excessive heat can accelerate the wear on brake rotors and might lead to the warping of these components. It is vital to choose brake rotors that are capable of withstanding this extra strain and efficiently managing the heightened temperatures from intense braking on challenging surfaces to maintain dependability and performance while steering clear of worn out brake rotors.

So what’s the impact when rotor wear occurs due to extreme thermal exposure? And how do we go about selecting rotors adept at dissipating such heat proficiently? Let us explore these topics further.

The Impact of Excessive Heat on Rotors

Heavy braking can produce extreme heat, causing damage to brake rotors including rotor runout, variations in thickness, and deep grooving that impair the effectiveness of your brakes. These issues may be intensified by worn-out brake pads which, when heated excessively, contribute to creating hard spots on the rotor surface resulting in uneven wear and vibrations during braking.

When subjected repeatedly to high temperatures from intense braking conditions, stress cracks are likely to develop on the rotors leading to reduced performance and increased safety hazards. Consequently, if you notice your steering wheel shaking while applying the brakes, this could indicate a problem with warped or unevenly worn brake rotors caused by excessive heat buildup.

Choosing Rotors That Dissipate Heat Effectively

As mentioned earlier, thicker brake rotors dissipate heat more efficiently, thereby minimizing the chances of performance issues on demanding terrains. High-carbon cast iron rotors enhance heat dissipation and offer greater resistance to thermal stress in rough driving conditions.

Rotors with internal vanes use a centrifugal pump effect to expel hot air and draw in cool air, aiding in temperature regulation during use. Vented rotors, with their space between rotor surfaces, offer superior heat dissipation over solid rotors, particularly for vehicles that encounter high brake temperatures.

Summary

We’ve just ridden through the rocky terrains of brake rotors. Our journey has taught us the importance of choosing the right rotors for uneven terrain, how different rotor types, their thickness, and material can impact braking performance, and why addressing heavy braking and heat dissipation is crucial.

But remember, just as rough terrains require robust rotors, they also demand responsible driving. So stay safe, and may your rides be as smooth as your new rotors!

Frequently Asked Questions

What types of rotors are best for uneven terrain?

Solid smooth rotors are best for uneven terrain as they are recommended for most daily driving scenarios.

How does rotor thickness impact braking performance?

Improved braking performance is achieved with thicker rotors, which excel at dispersing heat and thus prevent brake fade when heavy braking is necessary on challenging terrain.

What material is preferred for brake rotors?

Cast iron with high carbon content is favored for manufacturing brake rotors due to its superior thermal efficiency and capacity for heat dissipation, which renders it ideal for driving on rugged terrain.

What happens when rotors are exposed to excessive heat?

Excessive heat from heavy braking can cause rotor damage like runout, thickness variation, and severe grooving, which can reduce braking efficiency.

How can we choose rotors that dissipate heat effectively?

Opt for rotors that are both thicker and constructed from high-carbon cast iron, incorporating vented designs along with internal vanes to ensure efficient heat dissipation. This strategy aids in averting overheating while sustaining performance levels.

UNITED STATES

UNITED STATES