Testimonial Tuesday is back (Fleet Edition)!

Today we catch up with Fleet Manager David Nichols from Washington County/Johnson City EMS in Johnson City, TN.

Nichols oversees a fleet of 54 vehicles that provide emergency response to roughly 32,000 callers a year.

Click the video below to watch his testimonial.

Nichols understands that drivers who frequently carry heavy loads require heavy duty stopping power. That’s why his Fleet “rides exclusively on DFC products.”

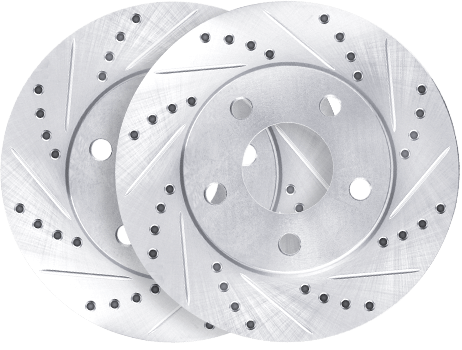

He adds, “We have found that the GEOSPEC high-carbon content rotors resist cracking. The 1214 Series Heavy Duty Brake Pads resist fading and stop well at all temperatures.”

There’s no doubt that when it comes to emergency response (especially with that kind of volume) you absolutely need performance and dependability.

DFC’s mission is to deliver quality and innovation by manufacturing OE quality brake products for all foreign and domestic vehicles, and for fleets of all sizes.

We recognize the ever changing conditions drivers of all vehicles face. Our products are designed to meet these needs, allowing drivers to stop when they need it most.

UNITED STATES

UNITED STATES