Elevate Your Drive with the DFC 4000 HybriDynamic Brake Pads

In the world of automotive excellence, brakes are not just a component; they are the cornerstone of vehicle safety and performance. Dynamic Friction Company (DFC) understands this all too well, which is why we’re excited to introduce the DFC 4000 HybriDynamic Brake Pads, a revelation in braking technology designed for the discerning driver. Whether you’re commuting daily or navigating challenging roads, these brake pads ensure you do so with unmatched confidence and control.

Why Choose DFC 4000 HybriDynamic Brake Pads?

- Superior Stopping Power: Engineered to provide optimal stopping performance, the DFC 4000 brake pads allow for a safe and reliable halt every time. Thanks to their advanced formulation, these pads cater to drivers who demand precision braking without compromises.

- Quiet and Clean: Say goodbye to noisy and messy drives. Our brake pads are not only quiet but also produce low dust, keeping your wheels cleaner and ensuring a smoother, more pleasant driving experience.

- Enhanced Durability and Performance: The DFC 4000 pads are built to last. They offer extended durability and stable friction performance across a wide temperature range, making them ideal for varying driving conditions. Additionally, these pads are rotor-friendly, promoting longer rotor life and reducing the likelihood of premature wear.

- Eco-Friendly Innovation: Complying with the 2021 California and Washington copper-free mandates, our brake pads are not only high-performing but also environmentally friendly. This copper-free formulation ensures that you’re investing in a product that cares for the planet as much as it does for your safety.

The Technical Edge

At DFC, we leverage only premium materials sourced from top-quality suppliers, ensuring that every component of the brake pad upholds our stringent standards. The DFC 4000 brake pads include features such as:

- Chamfered and slotted design to reduce braking noise.

- Scorched surfaces to minimize the initial break-in period and enhance stopping power right from the first use.

- Premium rubber-steel-rubber shims to improve NVH (noise, vibration, and harshness) characteristics, thus enhancing the overall stability and comfort of your drive.

Your Ideal Companion for Daily Driving

Designed specifically for daily drivers of passenger vehicles and light duty trucks, the DFC 4000 HybriDynamic Brake Pads ensure that every journey, no matter how mundane, is backed by superior brake technology. With these pads, DFC continues its commitment to delivering high-quality, high-performance braking solutions that meet the demands of modern drivers and the rigorous standards of current automotive innovations.

Experience the difference with DFC 4000 HybriDynamic Brake Pads – where technology, performance, and environmental responsibility come together to transform your driving experience. Upgrade to DFC and feel the immediate impact of world-class braking in your vehicle.

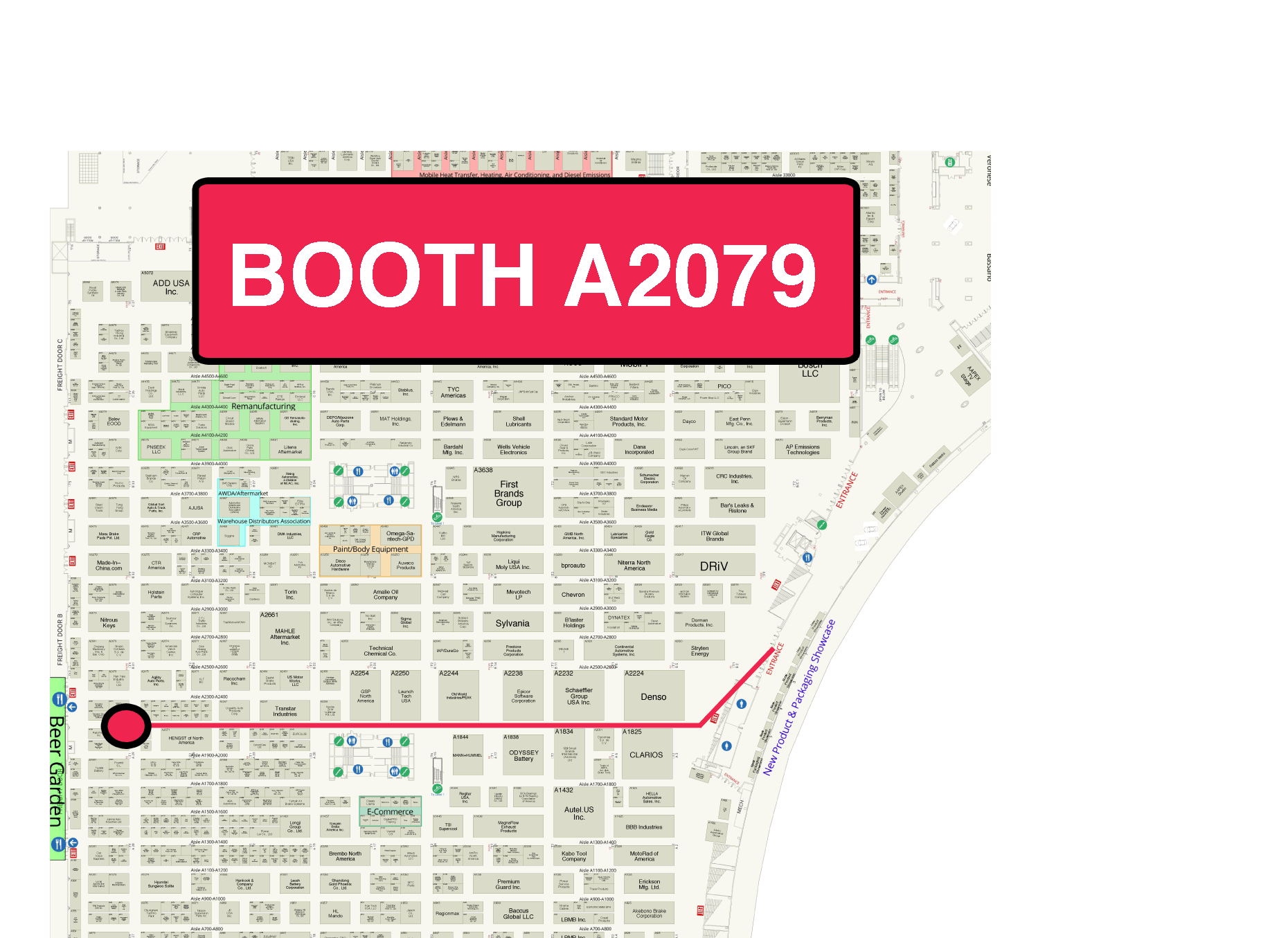

UNITED STATES

UNITED STATES